DeepSeek in Predictive Maintenance for Manufacturing Industries

Imagine your factory running smoothly, with no unexpected breakdowns. This is the promise of predictive maintenance, and DeepSeek is emerging as a powerful tool to make it a reality. This guide explores how DeepSeek is revolutionizing predictive maintenance in manufacturing. We’ll cover its benefits, challenges, and real-world applications. You’ll discover how this innovative AI can help manufacturers optimize their operations and reduce costs.

DeepSeek, a cutting-edge AI model, is making waves in various industries, and manufacturing is no exception. Its ability to analyze vast amounts of data and identify patterns makes it ideal for predicting equipment failures and optimizing maintenance schedules. This means less downtime, lower costs, and increased efficiency for manufacturers.

Understanding Predictive Maintenance and the Role of AI

Predictive maintenance uses data analysis and machine learning to anticipate when equipment will need maintenance. Instead of relying on fixed schedules or waiting for breakdowns, it proactively identifies potential issues. This approach minimizes downtime, reduces repair costs, and extends the lifespan of equipment.

AI plays a crucial role in predictive maintenance by analyzing large datasets from various sources. These datasets include sensor data, maintenance logs, and operational parameters. AI algorithms can identify subtle patterns and anomalies that indicate potential equipment failures. This allows manufacturers to schedule maintenance before a breakdown occurs, preventing costly disruptions.

Benefits of Predictive Maintenance

Predictive maintenance offers several key advantages over traditional maintenance approaches.

- Reduced Downtime: By predicting failures, manufacturers can schedule maintenance during planned downtime, minimizing disruptions to production.

- Lower Maintenance Costs: Predictive maintenance reduces the need for costly emergency repairs and extends the lifespan of equipment.

- Improved Equipment Reliability: Regular monitoring and proactive maintenance improve the overall reliability of equipment.

- Increased Efficiency: Optimized maintenance schedules lead to increased production efficiency and reduced waste.

- Enhanced Safety: Identifying potential equipment failures reduces the risk of accidents and injuries.

In conclusion, predictive maintenance is a proactive approach that leverages data and AI to optimize maintenance schedules, reduce costs, and improve overall operational efficiency.

The Rise of DeepSeek in the AI Landscape

DeepSeek is a relatively new player in the AI field, but it has quickly gained recognition for its advanced capabilities and cost-effectiveness. Developed in China, DeepSeek is challenging the dominance of established Western AI models. Its emergence has sparked both excitement and concern, particularly in industries that rely on AI-driven automation.

One of DeepSeek’s key advantages is its ability to process large amounts of data at a lower cost compared to some Western AI models. This makes AI-driven insights more accessible to manufacturers, especially those with tight budgets. However, its origin also raises concerns about data security and regulatory compliance.

DeepSeek’s Core Capabilities

DeepSeek’s success is built on a foundation of advanced technologies. These technologies enable it to deliver state-of-the-art AI solutions.

- Machine Learning (ML): DeepSeek uses various ML techniques to train algorithms that learn from data and make predictions.

- Natural Language Processing (NLP): DeepSeek’s NLP technologies enable machines to understand and generate human language.

- Computer Vision: DeepSeek’s computer vision technologies allow machines to interpret visual information.

- Deep Learning: DeepSeek utilizes deep learning to tackle complex problems that require high levels of abstraction.

- Data Analytics: DeepSeek’s data analytics capabilities enable organizations to make sense of large datasets.

These core capabilities allow DeepSeek to excel in various applications, including predictive maintenance.

How DeepSeek Enhances Predictive Maintenance in Manufacturing

DeepSeek can significantly enhance predictive maintenance in manufacturing by providing more accurate predictions and optimizing maintenance schedules. Its ability to process large datasets and identify subtle patterns makes it a valuable tool for manufacturers.

By integrating DeepSeek into their maintenance programs, manufacturers can reduce downtime, lower costs, and improve equipment reliability. This leads to increased efficiency and enhanced safety in the workplace.

Analyzing Sensor Data with DeepSeek

One of the key ways DeepSeek enhances predictive maintenance is by analyzing sensor data from equipment. Sensors collect data on various parameters, such as temperature, vibration, and pressure. DeepSeek can analyze this data to identify anomalies that indicate potential equipment failures.

For example, if a sensor detects an unusual increase in vibration, DeepSeek can flag this as a potential issue. This allows maintenance personnel to investigate the problem and take corrective action before a breakdown occurs. This proactive approach minimizes downtime and reduces the risk of costly repairs.

Optimizing Maintenance Schedules with DeepSeek

DeepSeek can also optimize maintenance schedules by analyzing historical maintenance data and operational parameters. By identifying patterns in this data, it can predict when equipment will need maintenance. This allows manufacturers to schedule maintenance during planned downtime, minimizing disruptions to production.

For example, if DeepSeek predicts that a particular machine will need maintenance in two weeks, the manufacturer can schedule the maintenance during a planned shutdown. This avoids the need for an emergency repair, which could disrupt production and cost the company a significant amount of money.

Real-Time Monitoring and Alerting with DeepSeek

DeepSeek enables real-time monitoring of equipment performance. It also provides alerts when potential issues are detected.

- Continuous monitoring of sensor data.

- Immediate alerts for anomalies.

- Proactive identification of potential failures.

- Reduced downtime and improved reliability.

Real-time monitoring and alerting ensures that maintenance personnel can respond quickly to potential issues, preventing costly breakdowns.

Applications of DeepSeek in Predictive Maintenance

DeepSeek has a wide range of applications in predictive maintenance across various manufacturing industries. Its ability to analyze data and identify patterns makes it a valuable tool for optimizing maintenance schedules and reducing downtime.

Here are some specific examples of how DeepSeek is being used in predictive maintenance:

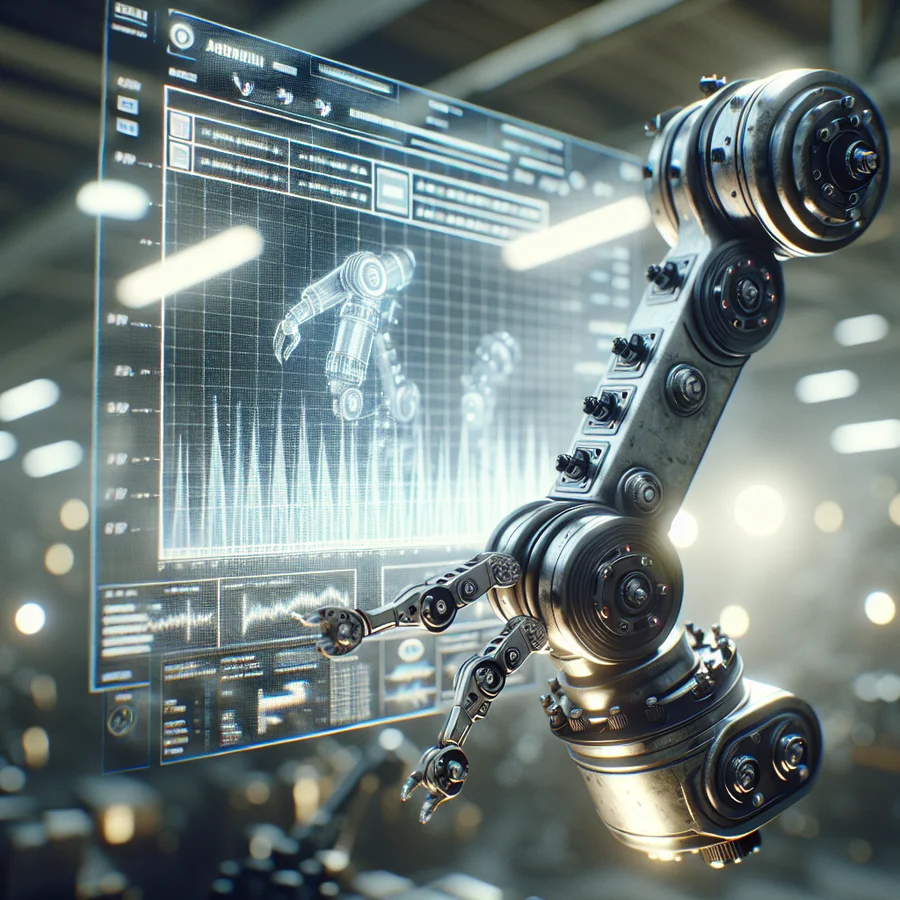

Predictive Maintenance in the Automotive Industry

In the automotive industry, DeepSeek is being used to predict equipment failures in assembly lines. By analyzing sensor data from robots and other equipment, it can identify potential issues before they lead to breakdowns. This allows manufacturers to schedule maintenance during planned downtime, minimizing disruptions to production.

For example, DeepSeek can analyze vibration data from a robotic arm to detect wear and tear. If it detects an unusual increase in vibration, it can alert maintenance personnel to investigate the problem. This proactive approach prevents the robotic arm from breaking down, which could halt production on the assembly line.

Predictive Maintenance in the Aerospace Industry

The aerospace industry uses DeepSeek to ensure the reliability of aircraft components. By analyzing data from sensors on engines and other critical systems, it can predict potential failures before they occur. This allows airlines to schedule maintenance during planned downtime, minimizing disruptions to flight schedules.

For example, DeepSeek can analyze temperature data from an aircraft engine to detect overheating. If it detects an unusual increase in temperature, it can alert maintenance personnel to investigate the problem. This proactive approach prevents the engine from failing during flight, which could have catastrophic consequences.

Predictive Maintenance in the Energy Industry

In the energy industry, DeepSeek is used to optimize the performance of power plants and prevent equipment failures. By analyzing data from sensors on turbines and other equipment, it can predict potential issues before they lead to breakdowns. This allows energy companies to schedule maintenance during planned downtime, minimizing disruptions to power generation.

For example, DeepSeek can analyze pressure data from a turbine to detect leaks. If it detects an unusual decrease in pressure, it can alert maintenance personnel to investigate the problem. This proactive approach prevents the turbine from failing, which could lead to a power outage.

Predictive Maintenance in the Pharmaceutical Industry

DeepSeek helps pharmaceutical companies maintain equipment and ensure product quality.

- Monitoring manufacturing equipment.

- Predicting potential failures.

- Ensuring consistent product quality.

- Reducing downtime and waste.

By predicting equipment failures, DeepSeek helps pharmaceutical companies maintain consistent product quality and avoid costly disruptions.

Challenges and Considerations for Implementing DeepSeek

While DeepSeek offers significant benefits for predictive maintenance, there are also challenges and considerations to keep in mind when implementing it. These challenges include data security, regulatory compliance, and the need for specialized expertise.

Manufacturers need to carefully evaluate these challenges and develop strategies to address them before implementing DeepSeek. This will ensure that they can realize the full benefits of this innovative AI model while minimizing potential risks.

Data Security Concerns

One of the primary concerns surrounding DeepSeek is data security. Given its origin in China, some manufacturers may be concerned about the potential for data breaches or government surveillance. It’s important to carefully evaluate the security protocols of DeepSeek and ensure that they meet your organization’s standards.

Manufacturers should also consider implementing additional security measures, such as data encryption and access controls, to protect their sensitive data. It’s crucial to have a robust data security strategy in place before implementing DeepSeek.

Regulatory Compliance

Another important consideration is regulatory compliance. Depending on your industry and location, there may be specific regulations that govern the use of AI and data analytics. Manufacturers need to ensure that their use of DeepSeek complies with all applicable regulations.

For example, in the European Union, the General Data Protection Regulation (GDPR) sets strict rules for the collection and use of personal data. Manufacturers need to ensure that their use of DeepSeek complies with the GDPR if they are processing personal data of EU citizens.

Need for Specialized Expertise

Implementing DeepSeek requires specialized expertise in AI, data analytics, and manufacturing processes. Manufacturers may need to hire new personnel or train existing employees to effectively use DeepSeek.

It’s important to have a team of experts who can manage the implementation of DeepSeek, analyze the data it generates, and develop strategies to optimize maintenance schedules. Without this expertise, manufacturers may not be able to realize the full benefits of DeepSeek.

Integration with Existing Systems

Integrating DeepSeek with existing manufacturing systems can be complex.

- Ensuring compatibility with legacy systems.

- Managing data flow between different systems.

- Addressing potential integration challenges.

- Planning for a smooth integration process.

Careful planning and execution are essential for successful integration.

The Future of DeepSeek in Manufacturing

The future of DeepSeek in manufacturing looks promising. As AI technology continues to evolve, DeepSeek is poised to play an increasingly important role in optimizing manufacturing processes and reducing costs.

With its advanced capabilities and cost-effectiveness, DeepSeek is likely to become a key tool for manufacturers looking to improve their operations and gain a competitive edge. However, it’s important to carefully evaluate the challenges and considerations before implementing DeepSeek to ensure that it’s the right fit for your organization.

Increased Adoption of AI in Manufacturing

The manufacturing industry is increasingly adopting AI technologies to improve efficiency and reduce costs. DeepSeek is well-positioned to capitalize on this trend, as it offers a cost-effective and powerful AI solution for predictive maintenance.

As more manufacturers realize the benefits of AI, the demand for DeepSeek is likely to increase. This will lead to further innovation and development of DeepSeek, making it an even more valuable tool for manufacturers.

Development of More Specialized AI Models

In the future, we can expect to see the development of more specialized AI models that are tailored to specific manufacturing processes. DeepSeek is likely to play a role in this trend, as it can be customized to meet the unique needs of different manufacturers.

For example, a specialized AI model could be developed to optimize the maintenance schedule for a particular type of machine. This would allow manufacturers to achieve even greater efficiency and reduce costs.

Integration with IoT and Cloud Computing

The integration of DeepSeek with IoT (Internet of Things) and cloud computing will further enhance its capabilities. IoT devices can collect data from equipment and transmit it to the cloud, where DeepSeek can analyze it in real-time.

This will allow manufacturers to monitor their equipment remotely and receive alerts when potential issues are detected. This proactive approach will minimize downtime and reduce the risk of costly repairs.

Ethical and Responsible AI

As AI becomes more prevalent, ethical considerations will become more important.

- Ensuring fairness and transparency.

- Addressing potential biases in AI models.

- Protecting data privacy and security.

- Promoting responsible AI practices.

Ethical and responsible AI practices are essential for building trust and ensuring that AI is used for good.

Conclusion

DeepSeek is emerging as a transformative force in predictive maintenance for manufacturing industries. Its ability to analyze vast datasets, identify patterns, and predict equipment failures offers manufacturers a powerful tool to optimize operations, reduce costs, and improve equipment reliability. While challenges such as data security and regulatory compliance need careful consideration, the potential benefits of DeepSeek are undeniable. As AI technology continues to evolve, DeepSeek is poised to play an increasingly important role in shaping the future of manufacturing, driving efficiency, and enhancing safety in the workplace. By embracing DeepSeek and other innovative AI solutions, manufacturers can unlock new levels of productivity and competitiveness in an increasingly digital world.

FAQs

What is DeepSeek?

DeepSeek is an advanced AI model developed in China. It is known for its ability to process large amounts of data and provide cost-effective AI solutions.

How can DeepSeek improve predictive maintenance?

DeepSeek can analyze sensor data, optimize maintenance schedules, and provide real-time monitoring and alerting to predict equipment failures and minimize downtime.

What are the challenges of implementing DeepSeek?

Challenges include data security concerns, regulatory compliance, the need for specialized expertise, and integration with existing systems.

Which industries can benefit from DeepSeek in predictive maintenance?

Automotive, aerospace, energy, and pharmaceutical industries are just a few examples of sectors that can benefit from DeepSeek’s predictive maintenance capabilities.

Is DeepSeek better than other AI models?

DeepSeek offers a competitive edge due to its cost-effectiveness and advanced capabilities, but the best model depends on specific needs and priorities.