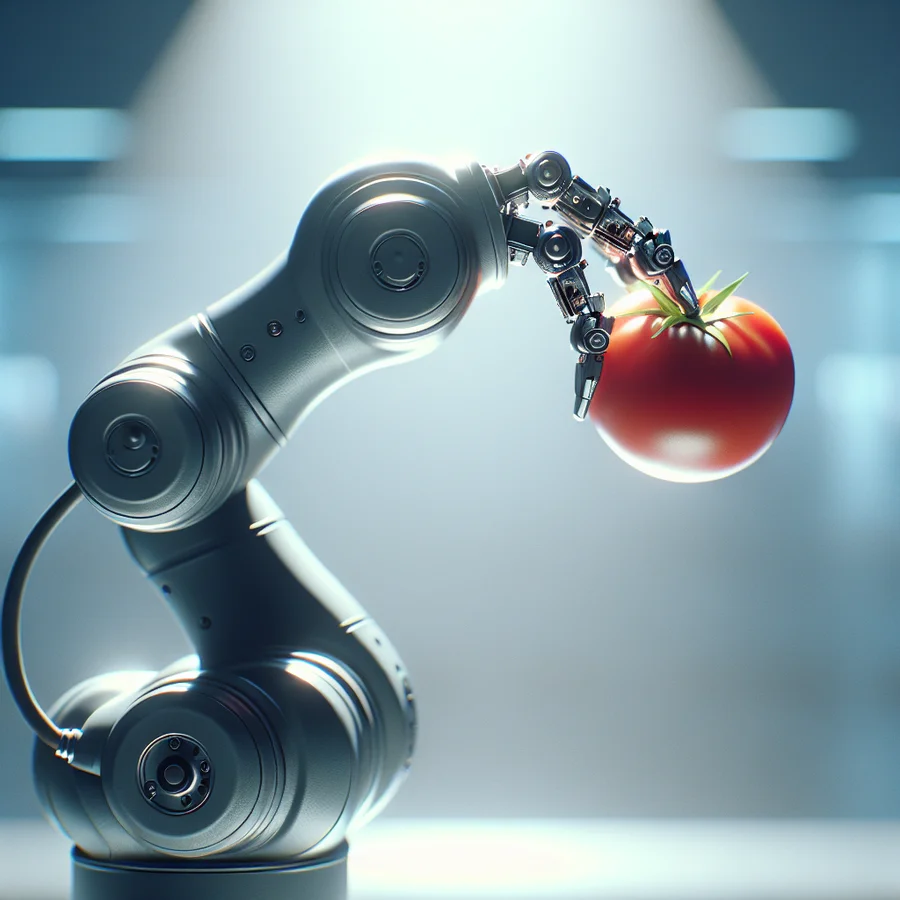

AI in Robotics: Automating Tasks and Enhancing Precision

Imagine robots that not only perform tasks but also learn, adapt, and make decisions. That’s the power of AI in robotics. This guide explores how artificial intelligence is revolutionizing the world of robotics, making them more efficient, precise, and capable than ever before. We’ll look at real-world applications and future possibilities.

AI in robotics is transforming industries by enabling robots to perform complex tasks autonomously. This leads to increased productivity, improved safety, and enhanced precision. This guide will cover everything you need to know about this exciting field. We will explore the current applications and future trends of AI in robotics.

Understanding the Basics of AI in Robotics

Before diving deep, let’s clarify what we mean by AI in robotics. It’s the combination of two powerful fields: artificial intelligence and robotics. This synergy creates robots that can think, learn, and act intelligently.

What is Robotics?

Robotics is the field of engineering that focuses on designing, building, and operating robots. These machines can perform tasks automatically or semi-automatically. Robots often handle jobs that are dangerous, repetitive, or require high precision.

What is Artificial Intelligence (AI)?

Artificial intelligence is the ability of a computer or machine to mimic human intelligence. This includes learning, problem-solving, and decision-making. AI algorithms enable machines to perceive their environment and respond accordingly.

The Synergy: AI and Robotics

When AI is integrated into robotics, it creates intelligent robots. These robots can analyze data, recognize patterns, and make autonomous decisions. This combination expands the potential applications of automation across various industries.

How AI Enhances Robotics Capabilities

AI significantly improves the capabilities of robots in several key areas. Let’s explore these enhancements.

Enhanced Perception

AI enables robots to perceive and interpret their surroundings with greater accuracy. Robots can detect obstacles, identify objects, and respond in real-time. This improved perception helps robots navigate complex spaces and interact safely with humans and other machines.

For example, consider underwater robots used for exploration. AI helps them navigate murky waters by combining visual and acoustic sensors. This allows them to operate effectively in challenging conditions.

Improved Decision-Making

AI empowers robots to make complex decisions autonomously. AI systems analyze data from sensors, cameras, and other input sources. This helps robots interact more effectively with their surroundings and perform tasks without constant human intervention.

Adaptive Learning

Machine learning, a subset of AI, allows robots to learn from data and improve their performance over time. Robots can identify patterns, adapt to new situations, and optimize their actions based on experience. This leads to increased efficiency and accuracy.

Real-Time Responsiveness

AI gives robots the ability to respond to changes in their environment in real-time. This is crucial for tasks that require quick adjustments, such as assembly, welding, and navigation. Robots can adapt their movements and actions based on sensor feedback.

Key Components of AI in Robotics

Several key technologies contribute to the success of AI in robotics. Let’s take a closer look at these components.

Machine Learning (ML)

Machine learning is a subset of AI that focuses on enabling robots to learn from data. ML algorithms identify patterns and trends in large datasets. This allows robots to fine-tune their operations and improve their accuracy over time.

For example, machine learning techniques like Artificial Neural Networks (ANNs) can improve the precision of industrial robot movements. This helps robots meet the tight tolerances needed in aerospace and other precision manufacturing.

Deep Learning (DL)

Deep learning takes machine learning a step further by using artificial neural networks. These networks model and understand complex patterns in large, unstructured datasets. With the ability to process vast amounts of information, robots can recognize patterns, make predictions, and even comprehend human commands.

Consider a manufacturing plant where robots use deep learning to spot defects more accurately than human inspectors. The neural networks analyze visual data in real-time, refining their ability to detect defects with each new image processed.

Computer Vision

Computer vision enables robots to “see” and interpret visual information. Robots can analyze images and videos to identify objects, recognize faces, and understand scenes. This is essential for tasks like quality control, navigation, and object manipulation.

Natural Language Processing (NLP)

Natural Language Processing allows robots to understand and respond to human language. Robots can interpret spoken or written commands and communicate with humans in a natural way. This is crucial for applications like customer service, healthcare, and collaborative robotics.

Applications of AI in Robotics Across Industries

AI in robotics is transforming various industries by automating tasks and enhancing precision. Let’s explore some key applications.

Manufacturing

In manufacturing, AI in robotics is used for assembly, quality control, and predictive maintenance. Robots can perform repetitive tasks with greater speed and accuracy, reducing errors and improving efficiency. Predictive maintenance helps identify potential equipment issues before they escalate, reducing downtime and costs.

For example, AI-driven robots can handle complex assembly tasks, leading to higher output rates and improved safety standards. These systems also enable flexible production lines and mass customization.

Healthcare

In healthcare, AI in robotics assists in surgeries, patient care, and logistics. Robots can perform minimally invasive surgeries with enhanced precision, reducing recovery times and improving patient outcomes. They can also transport medication, manage inventory, and disinfect rooms, reducing the workload on healthcare professionals.

Consider the Smart Tissue Autonomous Robot (STAR), which performed a laparoscopic surgery entirely on its own. This demonstrates the potential for AI to make complex procedures safer, more efficient, and more reliable.

Logistics and Warehousing

AI in robotics is revolutionizing warehouse operations by enhancing inventory management, order fulfillment, and logistics. Autonomous Mobile Robots (AMRs) use AI algorithms for real-time decision-making, enabling them to navigate dynamically, avoid obstacles, and adapt to changing environments.

These advancements address labor shortages and improve order fulfillment accuracy. AMRs can efficiently transport materials within a facility, optimizing route scheduling and load balancing.

Agriculture

In agriculture, AI in robotics enhances productivity and sustainability through precision farming, crop monitoring, and automated harvesting. Robots can monitor crops, analyze soil, and detect pests and diseases. This allows farmers to optimize water, fertilizer, and resource usage, leading to higher yields and more sustainable farming practices.

For example, the SentiV robot can inspect crops from above and below, using AI algorithms to detect pests, diseases, and plant needs. This provides farmers with precise insights to optimize their resources.

Mining

AI in robotics in mining brings significant gains to safety, precision, and efficiency. Autonomous mining vehicles navigate challenging terrains and hazardous areas without human drivers. This optimizes drilling and extraction processes and reduces the risk of accidents.

Rio Tinto, a global mining giant, deployed AI-driven autonomous drills at its iron ore mines. These drills use AI and sensors to navigate, position, and perform precise drilling with minimal human input, leading to a boost in productivity and better worker safety.

Construction

AI in robotics is transforming construction sites by enhancing safety, improving project management, and automating tasks. Real-time hazard detection systems use computer vision and wearable technologies to identify potential dangers before they lead to accidents. AI-powered project management tools enable better scheduling, budgeting, and resource allocation.

AI-driven robots are also being used for tasks such as bricklaying, concrete pouring, welding, and painting, improving efficiency and reducing labor costs.

The Role of AI in Different Types of Robots

AI plays a unique role in different types of robots, enhancing their capabilities and enabling them to perform specific tasks more effectively.

Autonomous Mobile Robots (AMRs)

AMRs use AI algorithms for real-time decision-making, enabling them to navigate dynamically, avoid obstacles, and adapt to changing environments. This intelligence allows AMRs to operate more flexibly in complex settings, such as warehouses and manufacturing plants.

Automated Guided Vehicles (AGVs)

AGVs leverage AI to optimize their operations within fixed routes. AI helps them with tasks like efficient route scheduling, load balancing, and fleet coordination, improving throughput in controlled environments like production lines.

Collaborative Robots (Cobots)

Cobots use AI to refine precision tasks like assembly and welding. They adjust force and positioning based on sensor feedback. AI also helps cobots recognize human gestures and adapt to unpredictable workflows, making them suitable for tasks that require direct human interaction.

The Impact of AI on Industrial Processes

AI is having a profound impact on industrial processes, leading to increased efficiency, reduced costs, and improved quality.

Increased Efficiency

AI-powered robots can perform tasks faster and more accurately than humans, leading to increased efficiency in manufacturing, logistics, and other industries. Automation reduces the need for human intervention, freeing up workers to focus on more complex tasks.

Reduced Costs

By automating repetitive tasks and reducing errors, AI helps reduce labor costs and operational downtime. Predictive maintenance minimizes equipment failures, cutting repair costs and extending equipment life.

Improved Quality

AI enables robots to perform tasks with greater precision and consistency, leading to improved quality in manufacturing and other industries. Machine vision systems can detect even the smallest defects, ensuring that only high-quality products reach the market.

Enhanced Safety

AI-driven robots can perform dangerous tasks, protecting human workers from harm. In mining, construction, and other hazardous industries, robots can navigate challenging terrains and operate in dangerous environments without human intervention.

Challenges and Considerations

While AI in robotics offers numerous benefits, there are also challenges and considerations to keep in mind.

Cost of Implementation

The initial investment required to implement AI in robotics can be significant. Purchasing, maintaining, and training staff to use robotic systems can be expensive, particularly for small to medium-sized enterprises (SMEs).

Ethical Concerns

The increasing reliance on automation raises ethical questions about accountability, particularly in cases of errors or accidents. Establishing clear guidelines on liability is essential to ensure responsible use of AI in robotics.

Resistance to Change

Healthcare professionals, construction workers, and other employees may be hesitant to adopt new technologies due to a lack of familiarity or fear of being replaced by machines. Training and awareness programs are crucial to overcoming this resistance.

Data Security and Privacy

AI systems rely on vast amounts of data, raising concerns about data security and privacy. Protecting sensitive information and ensuring compliance with data protection regulations is essential.

Future Trends in AI and Robotics

The field of AI in robotics is constantly evolving, with new trends and innovations emerging all the time. Let’s explore some of the key trends shaping the future of this technology.

Integration with the Internet of Things (IoT)

The integration of AI in robotics with the Internet of Things (IoT) is enabling seamless data sharing and monitoring. IoT-enabled robots can share data with other devices and systems, facilitating real-time adjustments and improvements.

Cloud Computing

Cloud computing enables robots to process data remotely and store vast amounts of information, boosting their capabilities without heavy onboard computing. This approach enhances efficiency, affordability, and scalability.

Nanorobotics

Nanorobotics represents the frontier of medical innovation. These microscopic robots can navigate the human body to perform tasks such as targeted drug delivery and precise removal of diseased cells, promising a future where treatments are minimally invasive and highly effective.

AI-Assisted Teleoperations

AI teleoperations provide remote control over robots, enabling precise maneuvering even from afar. This technology is particularly useful in hazardous environments or situations where human intervention is difficult or impossible.

Driverless Industrial Vehicles

AI-powered driverless industrial vehicles are changing the game for manufacturing, warehousing, and logistics. These vehicles boost efficiency, safety, and productivity by automating transportation tasks within facilities.

Conclusion

AI in robotics is revolutionizing industries by automating tasks, enhancing precision, and improving safety. From manufacturing to healthcare to agriculture, AI-powered robots are transforming the way we work and live. While challenges remain, the potential benefits of this technology are immense. As AI continues to evolve, we can expect even more innovative applications of robotics in the years to come. The future of AI in robotics is bright, promising a world where intelligent machines work alongside humans to create a more efficient, productive, and sustainable future.

Frequently Asked Questions (FAQs)

How is AI being used in robotics?

AI is used in robotics to enable autonomous navigation, decision-making, and task optimization. This allows robots to perform more complex and intelligent tasks without direct human input.

What is the future of AI in robotics?

The future of AI in robotics points toward greater integration of AI in everyday devices, smarter industrial robots, and further advancements in fields like healthcare and agriculture. We can expect to see more autonomous robots that can adapt to complex environments and work seamlessly with humans.

What is an example of a robot with AI?

Examples include medical robots used in surgeries, autonomous mobile robots (AMRs) used in warehouses, and collaborative robots (cobots) that assist humans in industrial settings. These robots use AI to perform tasks with greater precision, efficiency, and safety.

What is robotic process automation (RPA) in AI?

Robotic process automation in AI refers to the use of AI algorithms to automate repetitive tasks, freeing up human resources for more complex activities. This is commonly used in administrative tasks, data entry, and customer service.

What are the key benefits of AI in robotics?

The key benefits include enhanced precision, reduced operational costs, improved safety, and increased productivity. AI enables robots to perform tasks with a level of accuracy and consistency that is unattainable by humans, while also reducing the need for human intervention and minimizing errors.

How does machine learning benefit robotics?

Machine learning allows robots to learn from data and improve their performance over time. Robots can identify patterns, adapt to new situations, and optimize their actions based on experience. This leads to increased efficiency, accuracy, and adaptability.

What is the role of computer vision in robotics?

Computer vision enables robots to “see” and interpret visual information. Robots can analyze images and videos to identify objects, recognize faces, and understand scenes. This is essential for tasks like quality control, navigation, and object manipulation.

How does AI improve safety in the workplace?

AI-driven robots can perform dangerous tasks, protecting human workers from harm. In mining, construction, and other hazardous industries, robots can navigate challenging terrains and operate in dangerous environments without human intervention.

What are some challenges in implementing AI in robotics?

Some challenges include the cost of implementation, ethical concerns, resistance to change, and data security and privacy. Addressing these challenges requires careful planning, training, and the establishment of clear guidelines and regulations.

How is AI being used in construction?

AI is enhancing safety on construction sites through real-time hazard detection, wearable technologies, and proactive monitoring to predict and prevent accidents. AI-powered project management tools enable better scheduling, budgeting, and resource allocation, improving project efficiency and reducing costs. Generative AI is revolutionizing design and planning, while predictive analytics is used for risk management. Machine learning enhances quality control, and automation and robotics are used in construction tasks. IoT and real-time data enhance efficiency, and computer vision plays a crucial role in construction. AI is also used in construction supply chain management and for sustainable building practices. AI-driven collaboration and communication tools improve team coordination.