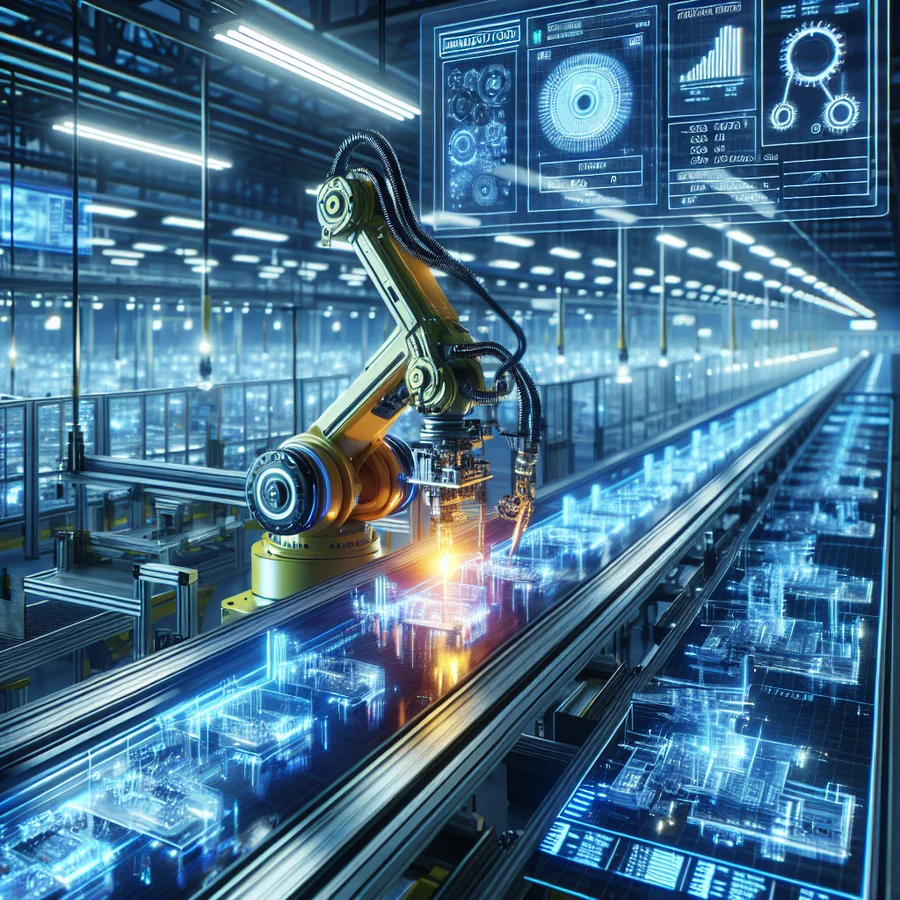

AI in Manufacturing: Optimizing Production and Supply Chains

Are you a manufacturer facing rising complexity, supply chain disruptions, and demanding customers? Traditional methods might not cut it anymore. You need more than just automation; you need intelligence. Artificial intelligence (AI) is revolutionizing manufacturing. It’s making operations smarter, faster, and more resilient.

This guide explores how AI in manufacturing is transforming production and supply chains. We’ll cover the benefits, challenges, and real-world examples. Discover how AI can help you optimize your processes, reduce costs, and gain a competitive edge.

Understanding AI in Manufacturing

What exactly is AI in manufacturing? It’s about integrating artificial intelligence technologies into manufacturing processes. The goal is to turn complex data into actionable insights. AI analyzes vast amounts of data from various sources. These sources include design files, machine performance logs, quality reports, and supply chain updates.

AI doesn’t just process this information; it interprets it. This helps identify inefficiencies and enables predictive decision-making. The real power of AI lies in its ability to:

- Optimize production processes.

- Predict machine failures before they happen.

- Adjust workflows in real time.

- Automate complex tasks.

This leads to reduced downtime, fewer bottlenecks, and increased throughput. All while using resources more efficiently. By embedding AI into digital manufacturing, you gain enhanced agility. Machines, processes, and supply chains continuously adapt and learn. This results in faster, more resilient operations that keep pace with evolving demands.

Key Benefits of AI in Manufacturing

AI is revolutionizing digital manufacturing. It boosts efficiency, agility, and decision-making. It helps manufacturers respond faster to challenges. It enables more effective innovation and optimizes the entire production process. Let’s explore some key benefits:

Reducing Expertise and Time with AI Co-Pilots

AI technology streamlines complex processes and tasks. This helps manufacturing professionals achieve results more efficiently. AI Co-Pilots provide guidance and support. They assist throughout the engineering, planning, and development stages. This reduces the need for extensive training and specialized expertise.

Developing Production Programs with Minimal Coding Knowledge

AI systems simplify the creation of production programs. They automate certain aspects and minimize reliance on expert coding knowledge. This allows manufacturing teams to focus on strategic decision-making and innovation. They can spend less time on technical details.

Reducing Downtime and Increasing Productivity with Prediction

AI’s predictive capabilities anticipate potential issues. They recommend preventive measures to minimize downtime. By proactively addressing maintenance needs and optimizing production schedules, AI helps increase overall productivity and efficiency.

Accelerating Troubleshooting and Optimizing Production Configuration

AI tools quickly identify and troubleshoot problems in the manufacturing process. This leads to faster resolutions and minimal disruptions. AI also optimizes production configurations. It uses real-time data and insights to maximize operational efficiency.

How AI Works in Supply Chains

Supply chain systems powered by AI help companies optimize routes. They streamline workflows, improve procurement, minimize shortages, and automate tasks end-to-end. A supply chain can become complicated. This is especially true for manufacturers who rely on partners to ship goods on time.

AI keeps all parts of a supply chain in balance. It finds patterns and relationships unlike a traditional system. These patterns optimize logistics networks. This spans from warehouses to cargo freighters to distribution centers.

Modern supply chains are expansive. They require thorough oversight to avoid disruptions. AI systems assist in forecasting. They help with demand planning and predict production and warehouse capacity. This is based on customer demand. Some use AI to gain insights from a broader data set. This data is collected from Internet of Things (IoT) devices across the supply chain.

AI can also track inventory levels and market trends. In inventory management, AI enhances supply chain visibility. It automates documentation for physical goods. It intelligently enters data whenever items change hands. This helps with transparency for the manufacturer. It provides valuable data for all stakeholders in the supply chain. AI’s enhancement of supply chain transparency offers unmatched time and cost savings. It also helps companies meet ethical and sustainability standards. These standards have historically been time-consuming and expensive to meet.

Benefits of AI in Supply Chains

An AI-powered supply chain has many potential benefits. It builds supply chain resilience and a stronger base for manufacturers. Let’s look at some of these benefits.

- Lower operating costs: AI learns complex behaviors and repetitive tasks. It tracks inventory quickly and accurately. AI solutions reduce overall operating costs. They identify inefficiencies and mitigate bottlenecks.

- Advanced real-time decisions: AI uses historical and real-time data. It makes real-time decisions, often with conversational answers. AI processes the data and analyzes the root of the problem. It suggests a solution, in that moment.

- Cut down on errors and waste: AI spots behaviors and patterns. Manufacturers and warehouse operators can train algorithms. These algorithms find flaws, such as employee errors and product defects. This happens long before bigger mistakes are made. AI can also streamline an ERP framework and be directly embedded.

- More tailored inventory management: AI forecasts demand with its use of inventory information. It gauges a customer’s interest in a product. It determines whether a customer’s demand is rising or falling and adjusts accordingly. It aids in a manufacturer’s decision-making process. It improves the accuracy of demand forecasting.

- Improved warehouse efficiency: AI, specifically ML models, helps lay out warehouses more efficiently. It evaluates the quantity of materials coming in. It improves service levels. The AI system can also plan the optimal routes for machinery and for workers. It can be an overall warehouse management powerhouse.

- Better supply chain sustainability: By using the predictive analytics that AI offers, companies make supply chains more sustainable. They become better for the environment. Manufacturers can use AI and ML models to optimize truckloads. They can predict the most efficient delivery routes. They can reduce product waste in the marketplace.

- Optimized operations through simulation: Supply chain managers want to better understand their operation. With AI-powered simulations, they gain insight. They understand and find ways to improve. AI, working alongside digital twins, can visualize potential supply chain disruptions. It visualizes external processes that might create unnecessary downtime through 2D visual models.

Challenges of Implementing AI in Manufacturing and Supply Chains

While AI offers tremendous potential, implementing it can be complex. Businesses should understand the challenges and risks before introducing this new technology.

- Downtime for training: When a company brings in a new technology, they need to train the individuals who will be interacting with it. Due to this necessity, downtime is likely to occur. It’s best to prepare and schedule accordingly to limit disruptions. All supply chain professionals should be aware of potential downtime. They should be transparent with partners that it might occur.

- Startup costs: There are several cost considerations in implementing AI. Along with the cost of the software to run the system, machine learning models are also an expense to consider. Some come prebuilt or can be built from scratch, if the company prefers that option. Either way, it’s important to train the model on your own clean, historical data before inputting AI algorithms.

- Complex systems: The work doesn’t stop as soon as the AI has been implemented. An AI system at a global scale is complex. It requires supply chain planners to constantly stay on top of how the tools are performing. They need to fine-tune as needed.

AI Risks to Consider

There are common risks when integrating AI in supply chains:

- Inaccuracy of data: AI is built and generated from large amounts of data. This data comes from a range of sources. Due to the nature of the origin of the data, inaccuracies and bias might be present. This would result in the spread of misinformation. For that reason, AI requires human review. This ensures that the data is fair, unbiased, and explainable.

- Overreliance on AI: Human interaction should be the superior solution. It should be the key expert in managing and handling supply chain risks. AI is a tool; it cannot build relationships. There is a misconception that AI can replace human intelligence. In fact, AI should augment it. If the technology fails, humans with expertise must keep the supply chain running.

- Security and privacy vulnerabilities: The increased collection and use of customer data for AI models also increases the risks of surveillance, hacking, and cyberattacks. Businesses must prioritize and safeguard consumers’ privacy and data rights. They should provide explicit assurances about how data is used and protected.

Steps to Prepare a Supply Chain for AI

Before implementing an AI solution, a business must prepare its legacy supply chain planning and management system. Here are some steps to take:

- Take stock of current logistics network: See what is and what isn’t working for your business. Take stock of the bottlenecks or areas where constant issues arise. Ensure that the AI technology is benefiting you in the best way possible. Identify pain points within the supply chain from end to end. Clean data to determine how structured and unstructured data should be used.

- Make a roadmap: Decide which issues your business wants to address first. Decide which ones are less of a necessity. It’s likely there are going to be multiple issues for a supply chain. Prioritization is key. Prioritize issues based on what your supply chain needs. Take on the more difficult, pressing issues first. Then delineate between the medium to lower importance.

- Design and select a solution: There are several types of systems to choose from. Which one a business selects will depend on its needs and the roadmap it has developed. At this point, a business might bring in a consultant or industry expert for guidance. Go through each system option to see which best fits the company’s supply chain management goals. Consider gaining professional insight from an industry expert.

- Begin to implement: The business needs to begin implementation of the AI technology at this point. The system integrator is likely going to be working with the internal IT team and the AI solution vendor to get things up and running. Prepare and educate a team on the AI technology. Be ready for setbacks or errors to occur in the process.

- Prepare employees: AI technology can be a major change. It requires training, patience, and a plan. Employees need to learn how to do their jobs. Open communication is key to successful AI technology implementation. Make a plan for communication to all employees before implementation begins. Consider the downtime that it takes to train employees and create a schedule.

- Continue to monitor: AI technology is always changing, improving, and adjusting. The teams who must manage the technology need to test and track what happens when adjustments occur. Periodic refinements can then be made. Regularly test the AI solution and troubleshoot its capabilities. Ensure that there is an organized tracking method for when testing occurs.

Examples of AI in Action

Many companies are already leveraging AI to transform their manufacturing operations. Here are a few examples:

- BMW: Employs AI-powered robots to automate stages of car manufacturing. This includes welding and painting. This has resulted in a 20% increase in production efficiency.

- Siemens: Utilizes AI to optimize factory operations. This includes predictive maintenance and process optimization. The AI system analyzes data from machinery to identify inefficiencies. It adjusts machine settings in real-time, leading to a 15% improvement in production efficiency.

- General Electric (GE): Uses AI to monitor its production lines for potential equipment malfunctions. AI detects anomalies in machine performance. It automatically suggests adjustments or schedules maintenance before breakdowns occur. This minimizes disruptions and enhances overall production output.

- General Motors (GM): Has implemented AI-powered production planning. This optimizes material usage across its automotive plants. By analyzing past production data and real-time inputs, GM has reduced material waste by 30%.

- Schneider Electric: Uses AI to optimize energy consumption in its manufacturing plants. AI systems continuously monitor equipment performance. They adjust energy usage based on demand patterns, leading to energy savings of up to 20%.

- Nissan: Uses AI-powered visual inspection systems to monitor and evaluate the surface finish of its vehicles. The AI system can detect minute defects. This includes minor dents or paint inconsistencies. It does this with 50% greater accuracy than human inspectors. This results in fewer errors during production and higher product consistency.

- Tesla: Implemented AI-driven quality inspections for its battery packs and vehicles. This significantly reduces human error in defect detection. The AI system identifies potential issues that human inspectors might overlook. This helps the company achieve a 90% reduction in product defects. This ensures fewer recalls.

- Bosch: Has implemented AI-powered predictive maintenance across its manufacturing facilities. This significantly improves equipment uptime and operational efficiency.

- Procter & Gamble (P&G): Has implemented AI-powered demand forecasting. This predicts consumer demand more accurately. This has allowed P&G to reduce excess inventory by as much as 25%. It improves its supply chain agility and reduces costs.

The Future of AI in Manufacturing

AI in manufacturing is not just a trend; it’s a fundamental shift. It’s reshaping the industry. From improving production efficiency to enhancing product quality and flexibility, AI helps manufacturers stay competitive. This is especially important in an increasingly dynamic market.

As the technology evolves, forward-thinking companies are using AI to drive innovation. They are optimizing operations and building smarter, more adaptive supply chains. The future holds even more exciting possibilities. Expect to see AI playing an even greater role in areas like:

- Generative design: AI will help create innovative product designs. It will optimize them for performance and manufacturability.

- Digital twins: AI will power more sophisticated simulations. This will allow manufacturers to test and optimize processes in a virtual environment.

- Human-robot collaboration: AI will enable robots to work more seamlessly with humans. This will create safer and more efficient work environments.

- Sustainable manufacturing: AI will help manufacturers reduce their environmental impact. This will be done by optimizing resource usage and minimizing waste.

Conclusion

AI in manufacturing is transforming how products are made and supply chains are managed. It offers significant benefits, from increased efficiency and reduced costs to improved quality and sustainability. While there are challenges to implementation, the potential rewards are too great to ignore. By embracing AI, manufacturers can unlock new levels of productivity, agility, and competitiveness in today’s rapidly evolving market.

FAQs about AI in Manufacturing

What industries use AI the most?

Several industry sectors heavily utilize AI for manufacturing and global operations to improve efficiency and reduce costs:

- Automotive: AI is utilized to optimize supply chain and manufacturing operations by enabling real-time tracking of components throughout the production process and improving predictive analytics for supply chain disruptions, which enhances overall efficiency and reduces lead times.

- Aerospace and Defense: AI is being used in manufacturing and supply chain operations to enhance predictive analytics for procurement, streamline production processes, and improve supply chain visibility, ensuring timely delivery and operational readiness.

- Electronics & High Tech: AI is deployed to optimize production and quality control by utilizing predictive analytics and automating intricate testing processes to ensure high-performance outputs and reduce defect rates.

- Consumer Goods: AI supports automated manufacturing, streamlines inventory management, and predicts market trends.

- Retail: AI improves demand forecasting, enhances inventory management, and empowers optimized, sustainable logistics planning.

- Pharmaceutical and Life Sciences: In this sector, AI enhances drug discovery, speeds up clinical trials, and improves supply chain logistics through better demand forecasting and inventory management, ensuring timely availability of critical medicines.

- Food and Beverage: The industry uses AI to maintain quality standards, improve production scheduling, and optimize supply chains through real-time analytics, leading to reduced waste and enhanced freshness of products.

Why are AI applications important in the industry today?

AI is crucial in the industry today because it significantly enhances efficiency, productivity, and decision-making processes. By integrating AI, industries can automate complex tasks, reduce errors, and improve quality through predictive analytics and real-time data monitoring. Moreover, AI-driven solutions facilitate the adaptability and optimization of operations, which ultimately lead to cost savings and improved competitiveness. As businesses face growing demands for faster, high-quality outputs, AI provides the necessary tools to meet these challenges effectively, setting new standards in performance and innovation.

What is the difference between AI and Machine Learning?

Artificial Intelligence is a broad field of computer science focused on creating systems capable of performing tasks traditionally requiring human intelligence. These tasks include decision-making, speech recognition, and language translation. Machine Learning (ML), on the other hand, is a subset of AI that involves the development of algorithms and statistical models that allow computers to learn and make decisions based on data. While AI encompasses the overall concept of machines acting intelligently, ML specifically focuses on the methods and processes by which machines gain this intelligence through data-driven learning.

What is the difference between Augmented Reality (AR), Artificial Intelligence (AI) and Virtual Reality (VR)?

Artificial Intelligence (AI) is the simulation of human intelligence in machines, enabling them to think, learn, and perform tasks that typically require human intelligence. AI enables machines to perform tasks such as speech recognition, image processing, natural language understanding, and problem-solving. It encompasses subfields like machine learning, computer vision, and natural language processing.

While Augmented Reality (AR) technology seamlessly incorporates virtual elements in 3D within a real environment in real-time, its core principle revolves around digitally merging the virtual and real worlds for seamless integration. In this case, it goes beyond simply overlaying virtual information onto an image and instead integrates synthetic information into the actual environment.

In contrast, Virtual Reality (VR) technology completely transports a user into a computer-generated reality. This immersion is typically facilitated by hardware devices like VR goggles, virtual reality headsets, or enclosed spaces with video screens that occupy the user’s entire field of view. VR provides an immersive experience within a 100% synthetic and digital environment.

What is generative AI in manufacturing and supply chain?

Generative AI in manufacturing and supply chain plays a pivotal role in transforming industry operations through enhanced efficiency and optimized processes. In manufacturing, it optimizes production processes, streamlining operations and fostering innovative production efficiencies.

For supply chains, generative AI enhances logistics by improving route planning and resource allocation, leading to cost savings and increased efficiency. Additionally, it empowers predictive analytics, facilitating informed decision-making by forecasting market trends and aligning supply with demand effectively.

How is AI used in Robotics?

AI is used in robotics to enhance capabilities by enabling robots to learn from their environments and adapt to different tasks. Through machine learning algorithms, robots can process large amounts of data to improve decision-making and problem-solving abilities. AI also facilitates autonomous navigation and precise object manipulation, making robots more efficient in complex and dynamic settings. These advancements allow for greater flexibility and functionality in industrial robotics, ultimately contributing to smarter and more versatile automated systems.

How is AI being used in production?

AI is used in production for predictive maintenance, quality control, process optimization, and automating repetitive tasks. It enhances decision-making with real-time data analysis, ensuring efficient and cost-effective operations.

How does AI improve efficiency in manufacturing?

AI improves efficiency by automating workflows, optimizing resource allocation, and reducing downtime. It enables real-time monitoring and predictive insights, helping manufacturers streamline processes and boost productivity.

Will manufacturing be replaced by AI?

AI will not fully replace manufacturing but will transform it by automating repetitive tasks and enhancing decision-making. Human expertise will remain essential for complex problem-solving, innovation, and strategic oversight.