AI in Logistics: Optimizing Delivery and Enhancing Customer Satisfaction

Are you tired of late deliveries and rising logistics costs? Artificial intelligence (AI) is revolutionizing the logistics industry. It’s improving efficiency, reducing expenses, and boosting customer satisfaction. Discover how AI is transforming delivery and supply chain management.

This guide explores the powerful impact of AI in logistics. We’ll cover everything from optimizing routes to predicting demand. Learn how AI can help your business thrive in today’s competitive market. Let’s dive in and explore the future of logistics!

Understanding the Role and Impact of AI in Logistics

Logistics and supply chain management are vital for the global economy. They ensure the smooth movement of goods. In today’s fast-paced market, efficiency and customer satisfaction are key. This is especially true with the rise of e-commerce and same-day shipping.

AI in logistics is a game-changer. It offers innovative solutions to automate tasks and refine operations. AI can strengthen security, reduce costs, and improve customer experiences. It’s transforming how businesses manage their supply chains.

Note: The market for AI in logistics and supply chain is expected to reach $64.46 billion by 2030. This represents a compound annual growth rate (CAGR) of 46.50% from 2023.

Ultimately, AI helps companies boost efficiency, elevate customer satisfaction, and increase profitability. It marks a new era of business excellence. Let’s explore the areas where AI is making a significant difference.

Key Benefits of AI in Logistics

AI offers many benefits to the logistics industry. These benefits enhance operations, reduce costs, and improve customer satisfaction. Let’s take a closer look at each of these areas.

Enhancing Operational Efficiency with AI

AI can significantly improve operational efficiency in logistics. It can lead to better resource allocation and smarter routing. AI systems automate routine tasks. This reduces human errors and accelerates data analysis. Decisions become faster and more accurate.

Machine learning, a branch of AI, continuously improves logistics operations. It provides data-driven insights that enhance decision-making. AI analyzes vast amounts of data. This helps predict future production and transportation volumes. Logistics managers can optimize supply chain planning and minimize stockouts.

AI also optimizes processes like route planning and warehouse management. It analyzes traffic and weather patterns. This helps identify the most efficient routes. It reduces vehicle wear and enhances delivery reliability. This proactive approach streamlines operations and creates a resilient supply chain.

Reducing Operational Costs with AI

AI in logistics can dramatically cut operational costs. It optimizes transportation routes and reduces empty travel miles. This minimizes fuel consumption and carbon emissions. Supply chains become more sustainable.

AI automates manual processes and streamlines operations. This leads to significant cost savings. This is especially true in warehouse operations and order processing. Accurate tracking and prediction improve inventory management. This ensures optimal stock levels and minimizes overstock and stockouts.

By enhancing inventory management and optimizing processes, AI contributes to substantial cost reductions. It also improves resource utilization, leading to greater efficiency.

Improving Customer Satisfaction with AI

AI applications enhance customer satisfaction by providing real-time updates. They also improve customer service interactions. Predictive analytics can mitigate potential delays. It uses real-time data for quick adjustments. This ensures timely deliveries and enhances the customer experience.

AI identifies patterns and trends in customer behavior. This helps businesses adjust to demand and provide more accurate delivery times. Natural Language Processing (NLP) is another AI application. It enhances customer service by understanding and responding to customer inquiries effectively.

Real-time visibility of delivery assets fosters transparency and trust. This leads to better customer satisfaction. Leveraging AI in logistics not only boosts efficiency and reduces costs but also enriches customer experiences.

AI Applications in the Logistics Sector

AI has diverse and impactful applications in the logistics sector. These range from route optimization to predictive maintenance. They also include inventory management and demand forecasting. These applications streamline operations and enhance efficiency.

Employing AI technologies allows logistics firms to lower costs and shorten delivery times. It also improves overall operational safety. Generative AI enhances logistics by processing large amounts of data. It analyzes complex variables, improving operational efficiency.

As logistics companies continue to adopt AI, the landscape is transforming. It’s becoming a more efficient and resilient sector. Let’s delve into specific AI applications and their practical benefits.

Demand Forecasting with AI

Traditional demand forecasting relies on historical data and market analysis. It also uses intuition to predict future consumer demand. However, these approaches often fall short in today’s dynamic market.

Traditional methods struggle to account for sudden market shifts and unexpected events. This can lead to inaccuracies in stock levels. It results in surplus inventory or shortages. This affects the company’s bottom line.

AI algorithms revolutionize demand forecasting. They leverage huge datasets, including historical sales and real-time market trends. They also use social media sentiment to predict future demand with higher accuracy. These algorithms apply machine learning techniques. They identify patterns and trends that may not be obvious to humans.

AI enables businesses to optimize their inventory levels. This reduces the risk of stockouts or excess inventory. It also improves efficiency in the supply chain. AI-driven demand forecasting allows for more agile responses to market changes. Businesses can better meet consumer needs while maintaining operational efficiency.

Route Optimization with AI

Efficient route optimization is critical for reducing transportation costs. It also improves delivery times and enhances customer satisfaction. Modern supply chains can be more complex than traditional ones. Goods may need to travel through multiple points before reaching the customer.

AI-powered route optimization algorithms offer a solution. They chart out the most efficient delivery routes. They analyze large amounts of data. This includes traffic patterns, weather conditions, and vehicle capacity constraints.

These algorithms adapt to real-time environmental changes. They suggest alternative routes that save time and fuel. By ensuring vehicles take the shortest routes, businesses can reduce their carbon footprint. They can also lower fuel consumption and ensure on-time deliveries.

Route optimization contributes to improved customer experience. Clients receive their orders faster and with greater reliability. This leads to increased customer satisfaction.

Warehouse Automation with AI

One area where AI drives efficiency is the automation of warehouse operations. By integrating AI-driven robotics, companies can enhance operational efficiency. They can also reduce operational costs.

Robots perform tasks like picking, packing, and sorting. Warehouses can operate around the clock. They maintain a pace unmatched by human labor. This level of productivity leads to faster order processing times. Companies can meet demand spikes without additional human resources.

Initial investments in AI-driven automation systems can be substantial. However, long-term savings more than make up for them. Automation reduces labor costs and the potential for human error. Robots can be deployed in hazardous environments. This reduces workplace accidents and associated costs.

AI systems can analyze vast amounts of data. This optimizes warehouse layout and inventory management. It also predicts future demand patterns. This allows processes to operate more efficiently. Warehouse managers can make more informed decisions.

Predictive Maintenance with AI

Equipment breakdowns can greatly affect workflow efficiency. They can lead to significant financial losses and reduce customer satisfaction. Traditional maintenance schedules run the risk of unexpected equipment failures. They can also lead to unnecessary maintenance activities, driving up costs.

Predictive maintenance, powered by AI and machine learning, analyzes data from equipment sensors. It predicts when machinery is likely to fail. Sensors can detect subtle changes in vibration or temperature. AI algorithms analyze this data. They compare it against known failure patterns to predict potential malfunctions.

Warehouse managers can schedule maintenance just in time to avoid downtime. This proactive approach ensures higher equipment reliability. It optimizes maintenance schedules and reduces costs associated with breakdowns.

AI-Powered Delivery Management: Transforming Last-Mile Delivery

Last-mile delivery is the final step in getting products to customers. It’s often the most complex and costly part of the shipping process. Optimizing it can lead to significant improvements. These include efficiency, cost savings, and customer satisfaction. Here are ways AI is revolutionizing last-mile delivery:

- Smart Route Optimization: AI uses data analytics to find the most efficient routes. It considers real-time traffic, road conditions, and weather forecasts. This reduces travel time and fuel consumption.

- Order Batching and Sequencing: AI groups multiple deliveries headed for the same locations. It plans efficient delivery sequences. This increases efficiency and reduces costs.

- Dynamic Real-Time Rerouting: AI systems monitor traffic and road closures. They recalculate routes to avoid delays. This ensures faster and more reliable deliveries.

- Predictive Delivery Time Estimates: AI analyzes factors like traffic and delivery volume. It predicts accurate delivery times. This enhances customer experience and increases transparency.

- Automated Locker Systems: AI-powered lockers provide a secure way for customers to receive packages. They are accessible 24/7. This offers convenience and reduces failed deliveries.

- AI-Driven Customer Support: AI handles inquiries about delivery status through chatbots. This provides fast responses and reduces workload on human representatives.

- Sustainability Through AI: AI optimizes delivery routes and reduces fuel consumption. It helps plan eco-friendly delivery options. This lowers the carbon footprint and enhances brand image.

AI is transforming the last-mile delivery landscape. By implementing AI-driven solutions, companies can significantly improve their delivery efficiency. They can also reduce costs and enhance customer satisfaction. These innovations provide a competitive edge in the demanding logistics sector.

Real-World Examples of AI in Logistics

Real-world examples illustrate AI’s impact on improving supply chain efficiency. Companies like Amazon and FedEx leverage AI to optimize their operations. These examples provide insights into how AI is being implemented.

Amazon’s AI-Powered Warehousing

Amazon uses robots for picking, packing, and sorting items in its warehouses. These robots enhance operational efficiency. They automate warehouse tasks and increase speed and accuracy. Machine learning algorithms optimize warehousing processes. They ensure inventory levels are managed effectively.

FedEx’s Predictive Analytics

FedEx employs AI-driven sorting systems to enhance efficiency. These systems automate sorting processes. They can sort up to 1,200 parcels per hour. By utilizing predictive analytics, FedEx can forecast potential delivery delays. This enhances the customer experience by providing more accurate delivery times.

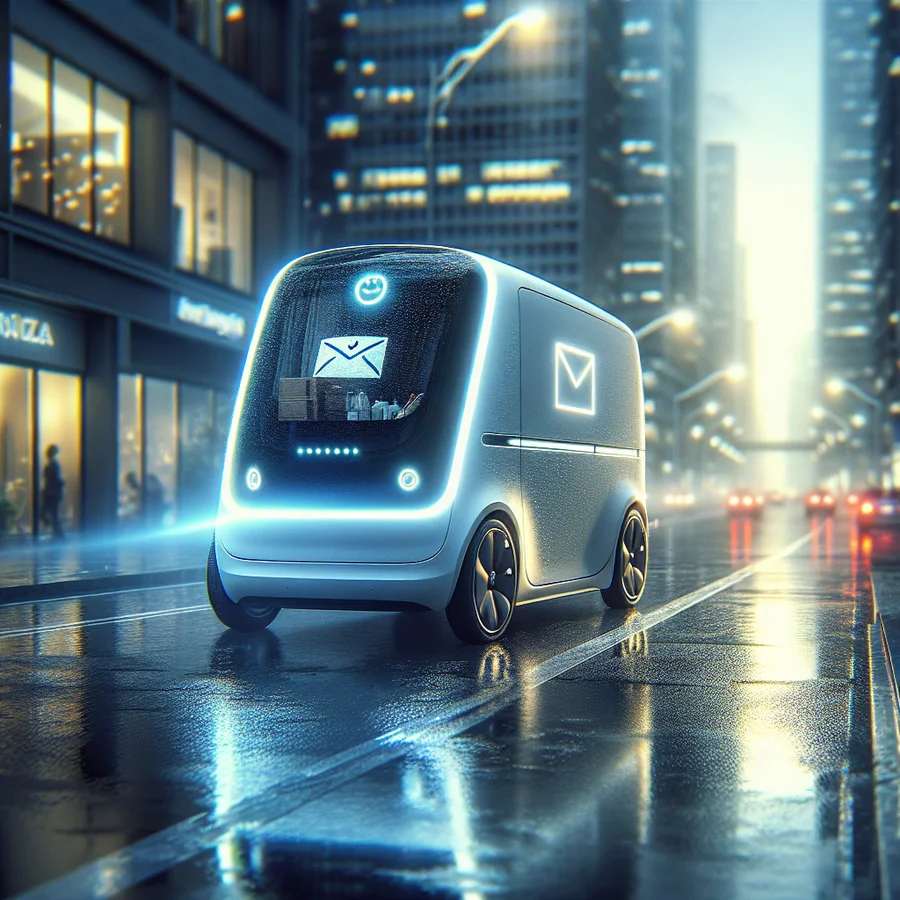

Nuro’s Autonomous Delivery Vehicles

Nuro utilizes AI-powered autonomous vehicles for last-mile delivery. These vehicles optimize last-mile delivery operations. They reduce the need for human drivers and minimize environmental impact. Nuro’s vehicles navigate complex urban settings, ensuring efficient deliveries.

Challenges and Considerations for AI in Logistics

Implementing AI in logistics presents challenges. These must be thoughtfully addressed to maximize its benefits. Let’s consider some key challenges.

- Data Privacy and Security: Ensuring data privacy is critical. Implement robust cybersecurity measures and comply with data protection regulations.

- Ethical Concerns: Deploy AI ethically. Address potential biases in algorithms. Ensure fairness and transparency in AI decision-making.

- Integration with Existing Systems: Integrating AI with legacy systems can be complex. Plan carefully and ensure compatibility.

- High Initial Costs: AI implementation can be expensive. Develop a phased approach to manage costs. Focus on ROI and long-term benefits.

- Lack of Skilled Professionals: There’s a shortage of AI experts. Invest in training and development. Partner with AI specialists to bridge the skills gap.

Addressing these challenges is crucial for successful AI implementation. By carefully planning and mitigating risks, businesses can unlock the full potential of AI in logistics.

Future Trends in AI and Logistics

AI technologies are increasingly solving challenges in logistics. The costs associated with AI are decreasing. This makes adoption more feasible. Future possibilities for AI include better data integration and more accurate forecasting.

Logistics firms face ongoing challenges in integrating AI with existing systems. However, AI’s ability to transform logistics is undeniable. Let’s explore some future trends.

- Autonomous Vehicles: Self-driving trucks and drones will revolutionize delivery. They will reduce labor costs and improve efficiency.

- AI-Powered Supply Chain Management: AI will optimize the entire supply chain. This includes planning, sourcing, and delivery.

- Predictive Analytics: AI will provide more accurate demand forecasting. This will help businesses optimize inventory and reduce waste.

- Robotics and Automation: Robots will perform more tasks in warehouses and distribution centers. This will increase efficiency and reduce human error.

- Personalized Delivery Experiences: AI will enable personalized delivery options. This includes customized delivery times and locations.

The future of AI in logistics is bright. Businesses that embrace these trends will gain a significant competitive advantage. They will be better equipped to meet the demands of the future.

Conclusion

AI in logistics is no longer a futuristic concept. It’s a present-day reality that’s transforming the industry. From optimizing routes to predicting demand, AI offers powerful solutions. These solutions improve efficiency, reduce costs, and enhance customer satisfaction.

By embracing AI, logistics companies can stay ahead of the curve. They can meet the evolving demands of the market. The future of logistics is intelligent, efficient, and customer-centric. Are you ready to embrace the AI revolution?

FAQs

How does AI improve route optimization in logistics?

AI improves route optimization by analyzing real-time data. This includes traffic, weather, and road conditions. It determines the most efficient delivery paths. This reduces delivery times and fuel consumption. It also leads to cost savings and faster deliveries.

What are the key benefits of using AI in warehouse automation?

AI in warehouse automation enhances operational efficiency. It reduces labor costs and minimizes human error. Robots can operate around the clock. They maintain a pace unmatched by human labor. This leads to faster order processing and better resource utilization.

How does AI contribute to sustainability in logistics?

AI contributes to sustainability by optimizing delivery routes. This reduces fuel consumption. It also helps plan eco-friendly delivery options. These practices lower the carbon footprint of delivery operations. They align with corporate sustainability goals.

What are some challenges in implementing AI in logistics?

Some challenges include data privacy and security concerns. There are ethical considerations and integration complexities with existing systems. High initial costs and a lack of skilled professionals can also pose challenges. Careful planning and mitigation strategies are essential for successful AI implementation.

What future trends can we expect to see in AI and logistics?

Future trends include the use of autonomous vehicles and AI-powered supply chain management. We can expect more accurate predictive analytics and increased robotics and automation. Personalized delivery experiences will also become more common. These trends will reshape logistics operations and improve customer satisfaction.